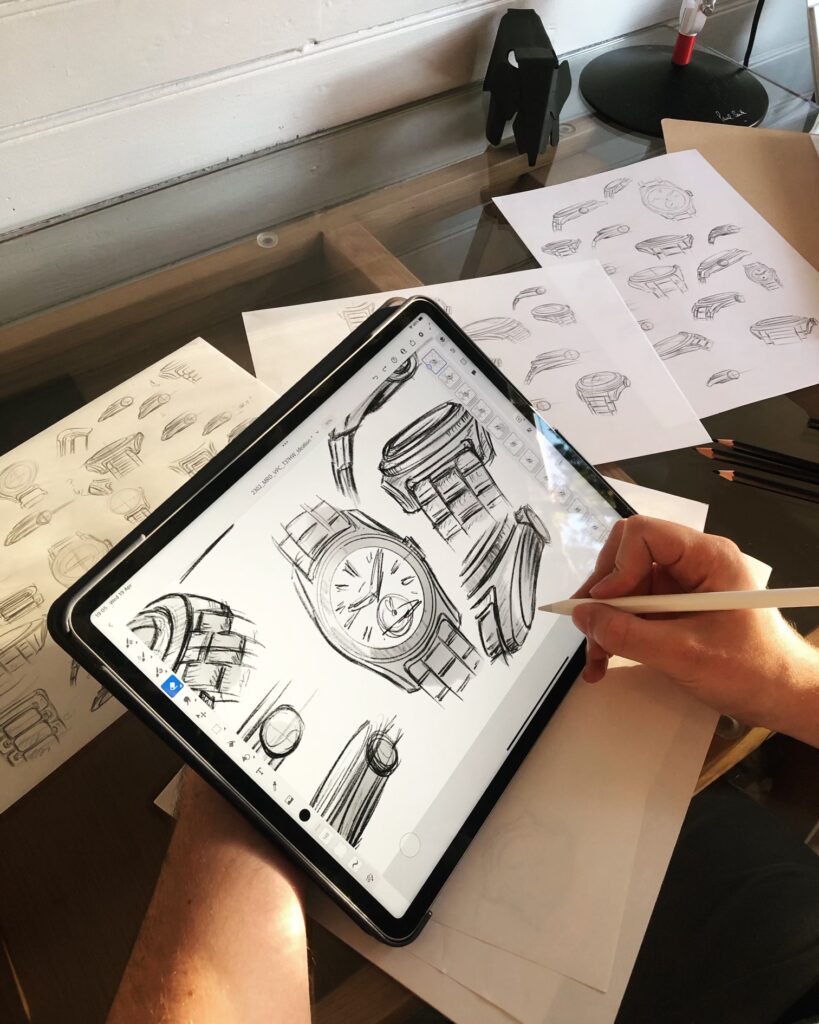

Welcome to part III of the series of articles on the development of my own watch, the VPC Type 37HW. In the previous episode, we saw how the creative watch design was developed through 3D printed prototypes into something that can actually be produced. This time, I take a closer look at the steps that follow - finding and bringing manufacturers together. That may not sound very interesting, but it was perhaps the most instructive step for me so far. And I've seen quite a bit in the watchmaking world anyway....

Text: Thomas van Straaten

Finding manufacturers and closing the necessary deals is a tactical and political game. A game, moreover, that is generally kept secret from consumers. All the more interesting, then, to shed some light on it here.

Three paths from design to product

There are roughly three ways to go from a design like mine to get to a working product. The first is the easiest, namely outsourcing the whole thing to an integrated manufacturer. These types of companies produce watches for third parties. They usually produce partly in-house and sourced the remaining parts from specialist manufacturers. In any case, they handle the final assembly of the final product.

You will then get a quote for the development of your watch and a price for the final watches at different quantities. That price is opaque because you don't know what the individual components like the dial, case, strap, hands and movement cost. You also don't know where those components come from. As a result, you also have relatively little influence on the specific components. What is and isn't possible often remains vague. You do get the convenience of a single point of contact in return.

You will then get a quote for the development of your watch and a price for the final watches at different quantities. That price is opaque because you don't know what the individual components like the dial, case, strap, hands and movement cost. You also don't know where those components come from. As a result, you also have relatively little influence on the specific components. What is and isn't possible often remains vague. You do get the convenience of a single point of contact in return.

The second way is the opposite route. You then start sourcing every part yourself from specialists. So you have a dial made at a 'cadranier' to your exact specifications. You then have all the parts come together at a party that does the assembly. You now have ultimate transparency and flexibility, but also a significantly more complex project to manage.

The third -and chosen by me- route is a kind of middle way. I work with a Swiss party that provides assembly and also helps with sourcing the parts. They help designate the right specialists and coordinate that everything also comes together perfectly later on. As a result, I know what the components cost and where they come from. I also have ownership and control over everything, so I am always free to switch to another party with my technical drawings or replace suppliers. Not unimportant if you want to set up solid business operations!

Finding manufacturers is harder than it looks

Finding manufacturers is harder than it looks

Now you may be thinking, 'Why do you need such a middleman? Surely you can just Google your suppliers and approach them yourself?' So that's not how it works, I discovered through trial and error.

The watch world is quite discreet. This is partly due to the in-house myth that many brands like to perpetuate. You must, as a consumer, feel that everything is made under one roof, by the watch brand itself. Of course, this is far from always the case. Historically, there were always specialists making parts and brands putting them together. Today, brands are not so proud of this and make sure their suppliers operate in silence. Many of these companies don't even have a website.

On top of that, they are often already running at full capacity. If they then have a rookie from the Netherlands on the e-mail with a complicated request for 300 watches, they still prefer to prioritise existing A-brand customers who have thousands of watches made at once. Understandable, of course. Although it was occasionally explained to me quite literally. "You mean nothing to us, you are a dreamer". I would be lying if I said I didn't feel discouraged at times. "Is this ever going to work?"

An intermediary eases up

Fortunately, my designer, Max Resnick, put me on the trail of a Swiss party that could act as a liaison, as well as provide assembly and servicing. That turned out to be worth its weight in gold. I visited them to get a good look in each other's eyes and tour the workshop. After a good first impression, they went to work with my set of wishes and requirements.

And that's quite a package. VPC becomes distinctive when microbrand due to the fact that I operate in a higher segment than most. In terms of features and finishing, I really want the very best and most manufacturers are not used to hearing that from new players. To give an example, most small brands use generic, mass-produced steel straps. I worked with Max to create a completely in-house design with my own specifications. That is unusual and complicates negotiations.

And that's quite a package. VPC becomes distinctive when microbrand due to the fact that I operate in a higher segment than most. In terms of features and finishing, I really want the very best and most manufacturers are not used to hearing that from new players. To give an example, most small brands use generic, mass-produced steel straps. I worked with Max to create a completely in-house design with my own specifications. That is unusual and complicates negotiations.

Fortunately, my liaison knew how to point out the right parties for the trickier parts like the strap and the double-layer dial with ceramic lume. Those parties now took me seriously because they knew my liaison and designer. Yet even that turned out not to be enough...

Fortunately, my liaison knew how to point out the right parties for the trickier parts like the strap and the double-layer dial with ceramic lume. Those parties now took me seriously because they knew my liaison and designer. Yet even that turned out not to be enough...

Proving you are a worthy partner

If you think the red carpet is being laid out for you as a new client, you are wrong. Items with vague titles like 'development' regularly appeared on quotations. I asked my liaison why I had to pay for development when the technical drawings were already ready and a separate item was quoted for 'tooling' (think making the necessary dies and moulds).

"Well, that's actually more to cover the risk of you not making it. And to see if you are a serious player," he explained to me. My reasoning was that a serious player does not put down thousands of euros for a fictitious cost. Let me say we ended up somewhere in the middle....

Prototyping

Prototyping

You will understand that after the flashy, creative design phase, this was a rather frustrating and syrupy episode. But fortunately, it was not in vain. In the end, we got some fantastically skilled specialists together who should be able to produce a particularly high-quality watch for VPC. All the necessary deals are in place and they are now hard at work making four prototypes for me.

For me, this was a particularly instructive journey. I now work with parties that also produce for the biggest names in the watch world. That's a world you don't normally get an insight into. I received a lesson in humility, but I am also proud that I managed to set up production without compromising. I still haven't had to compromise anything on the original, extremely ambitious concept of the watch.

The next three months will show whether this production line can deliver what I am looking for. If it does, I may finally be able to show a real watch in the next episode! I hope you'll read along again then!